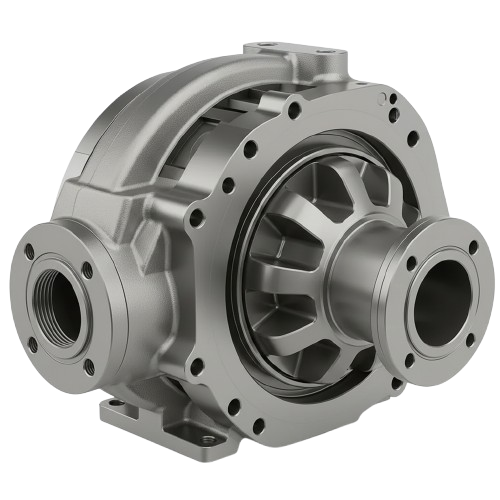

Industrial 3D CAD Modeling & 3D Printing Services

Production-Ready CAD Models. Physical Prototypes. One Integrated Workflow.

We deliver industrial-grade 3D CAD modeling and 3D printing services engineered for real-world manufacturing, scalability, and reuse. Our CAD models are built to perform across design validation, manufacturing, visualization, sales, and physical prototyping.

Industrial CAD Modeling That Goes Beyond Design

In industrial environments, CAD data travels far beyond engineering teams — into manufacturing, quality, sales, marketing, training, and digital systems.

When CAD models are created without this full lifecycle in mind, it leads to:

We eliminate those gaps by designing CAD models with manufacturing intent, assembly logic, and multi-department usability built in from day one.

Our Core Advantage

Industrial CAD Models Built Once. Used Everywhere.

Manufacturing-First CAD Modeling

Fit, tolerances, materials, and assembly sequence considered upfront. Geometry aligned with real production constraints.

Assembly-Accurate Modeling

Assemblies built as they exist in real life with correct interfaces, clearances, and motion logic.

Scalable & Parametric CAD Architecture

Feature-based and rule-driven modeling that supports revisions, variants, and product line expansion.

Cross-Platform CAD Compatibility

Support for SolidWorks, Inventor, Creo, AutoCAD, and Solid Edge platforms.

Industrial-Grade CAD Modeling Capabilities

Our CAD models are engineered for accuracy, reuse, and long-term value:

Applications Across the Product Lifecycle

One CAD Model. Multiple Business Outcomes.

Our CAD data supports:

CAD Modeling + Rendering + Video + 3D Printing

Because we manage CAD modeling, visualization, and prototyping under one workflow, your product data stays consistent across every output.

What this means for you:

Your CAD becomes a strategic digital and physical asset, not a static file.

3D Printing & Physical Prototypes

From CAD Models to Physical Parts — Seamlessly

In addition to industrial CAD modeling, we offer end-to-end 3D printing support through strategic partnerships with reputed manufacturing providers. We take your CAD model beyond the screen and deliver high-quality, production-grade 3D printed components.

CAD Models Optimized for 3D Printing

Because our CAD is created with fabrication intent, it translates cleanly into physical parts.

Applications

Technologies

Materials

How the Process Works

Industrial 3D CAD modeling

Based on your requirements

CAD optimization

For manufacturing or 3D printing

Technology selection

Technology and material selection

High-quality printing

High-quality 3D printing and finishing

Component delivery

Delivery of printed components

You work with one partner. We manage the rest.

Industrial Components & Systems We Support

Frequently Asked Questions

Are your CAD models manufacturing-ready?

Yes. All models are built with tolerances, assembly logic, and production intent from the ground up.

Do you support parametric and configurable designs?

Yes. We specialize in feature-based and rule-driven CAD modeling that supports easy modifications and variants.

Can the same CAD model be used for rendering and printing?

Absolutely. Our models are optimized for visualization, animation, and physical prototyping without requiring rework.

Which CAD platforms do you support?

We support SolidWorks, Inventor, Creo, AutoCAD, Solid Edge, and other major CAD platforms.

Build Industrial CAD Models That Scale Into Reality

Get production-ready CAD models and high-quality 3D printed prototypes — engineered for accuracy, reuse, and real-world performance.